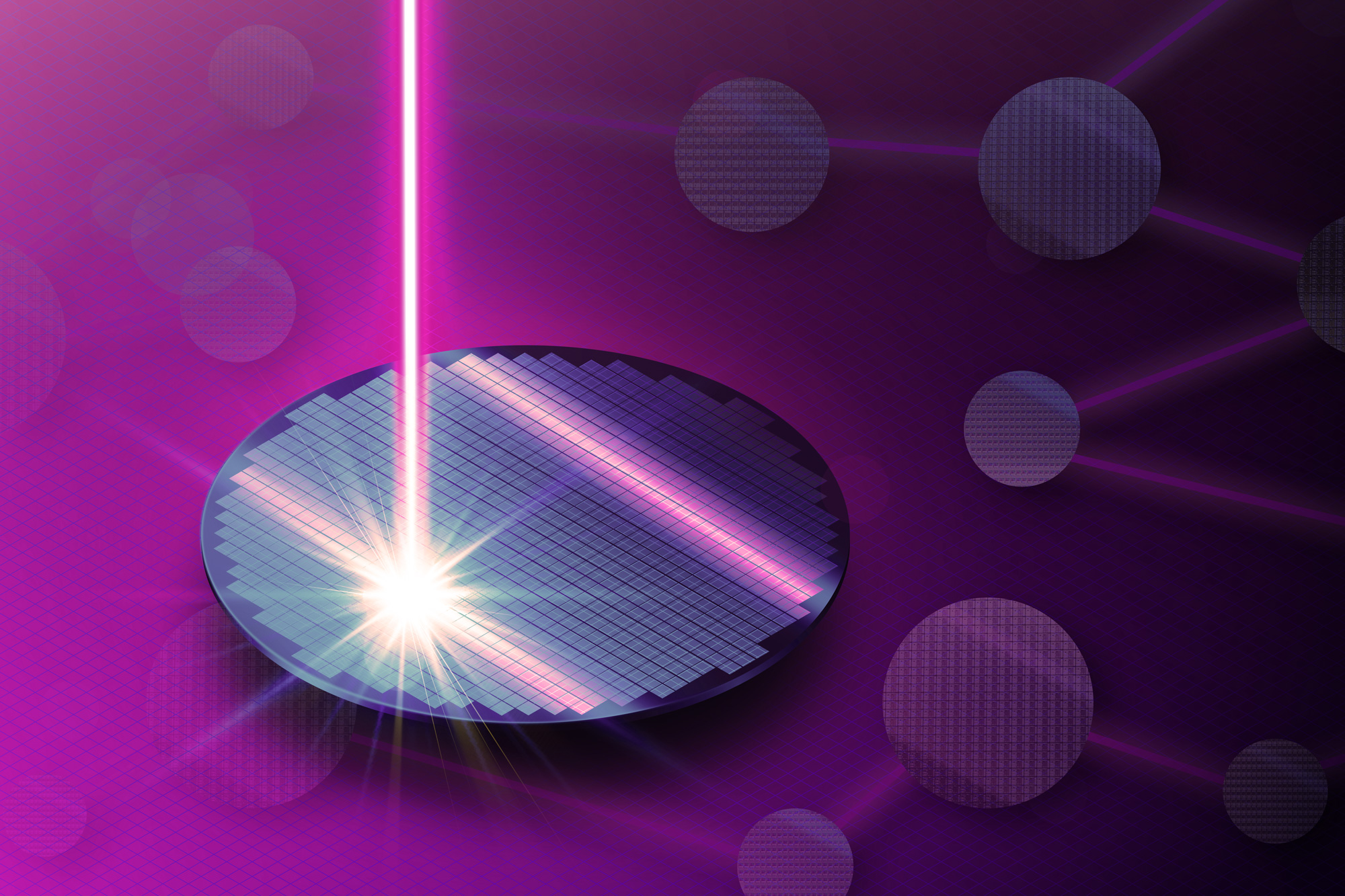

Photolithography involves manipulating light to precisely etch features onto a surface, and is commonly used to fabricate computer chips and optical devices like lenses. But tiny deviations during the manufacturing process often cause these devices to fall short of their designers’ intentions. To help close this design-to-manufacturing gap, researchers from MIT and the Chinese University of Hong Kong used machine learning to build a digital simulator that mimics a specific photolithography manufacturing process. Their technique utilizes real data gathered from the photolithography system, so it can more accurately model how…